Small Laboratory Blown film extruders

Upward Blown Film Downward Blown Film

|

Blown Film

Laboratory Extruders: Scroll down the page for description of models.

Click here to see the 12.5mm extruders in a 3 layer co-extrusion application. |

Micro Table Top Blown Film Line |

|

|

The film blowing attachment type LF-400 is equipped as follows: ¨ Large 2.3-meter high film tower with twin pillars of rigid extruded aluminum profiles. Sub cabinet of modern pleasing design, which incorporates the control cabinet as well as the air blower for the cooling ring. Whole assembly is fitted with four heavy-duty casters (two of the casters have locks to fix the unit in a permanent position). ¨ Roll width 400 mm, which can accommodate film lay flat widths of up to 300 mm. ¨ Pneumatically operated nip rolls with controls on sub cabinet. ¨ Film die mounted on the two aluminum pillars, adjustable in height to fit extruder flange. Film die diameter is a standard 50 mm, giving a blown film diameter of around 150 mm. (other die diameters can be supplied on request). Die mandrel equipped with spiral flow channels for uniform distribution of polymer melt around entire die area. All internal die parts are hard chromed and highly polished. Adjustable die centering for accurate film thickness control. ¨ Two digital self-tuning temperature controllers, one for the film die and the other for the S-adaptor to the extruder. The controllers are mounted on the sub cabinet of the unit. ¨ Large twin channel cooling ring for optimum cooling efficiency. The upper and lower channels are equipped with adjustable airflow lips. Air supplied from a 1 HP turbo blower. ¨ Film bubble stabilizing rods as well as synchronous adjustable film collapsing frame using polished teak wood slats. ¨ Infinitely variable speed drive of the nip rolls. ¨ Three guide rollers for downside feeding of the blown film. ¨ Inspection cabinet with lamps placed on downside of film tower. The lamps shine through the film for easy inspection of film quality. ¨ Film wind up rolls driven via an adjustable clutch by a variable speed motor for precise tensioning of the film. Easily removable film bobbin clamped onto a shaft with pinions, resting on two inclined racks. This system enables fast threading of new film and gives a tight wind-up. ¨ Electric cabinet as well as control cabinet in the sub cabinet, containing all controls such as two temperature controllers for the die, on/off push buttons for blower, nip roll and windup drives as well as pneumatic opening/closing of the nip rolls. The two variable speeds drives for the nip rolls and wind up rolls are controlled with scroll buttons on the digital controllers, displaying the film speed in meters per minute.

|

|

|

|

Compact Film Blowing Line type LF-250 with 20 mm, 30 L/D extruder Type LBE20-30/C This new line is designed to produce a professional film with optimum dispersion of colorants. The small internal volume of the die coupled to our smallest 20 mm extruders also gives minimum resin usage with fast color changeovers. The film blowing attachment is connected to our single screw bench top extruder type LBE20-30 with a C-clamp on the flange to the extruder. The attachment is built up on an individual self-supporting frame with lockable casters and thus can be easily removed from the extruder. Request a quote on this line - Click Here |

|

|

|

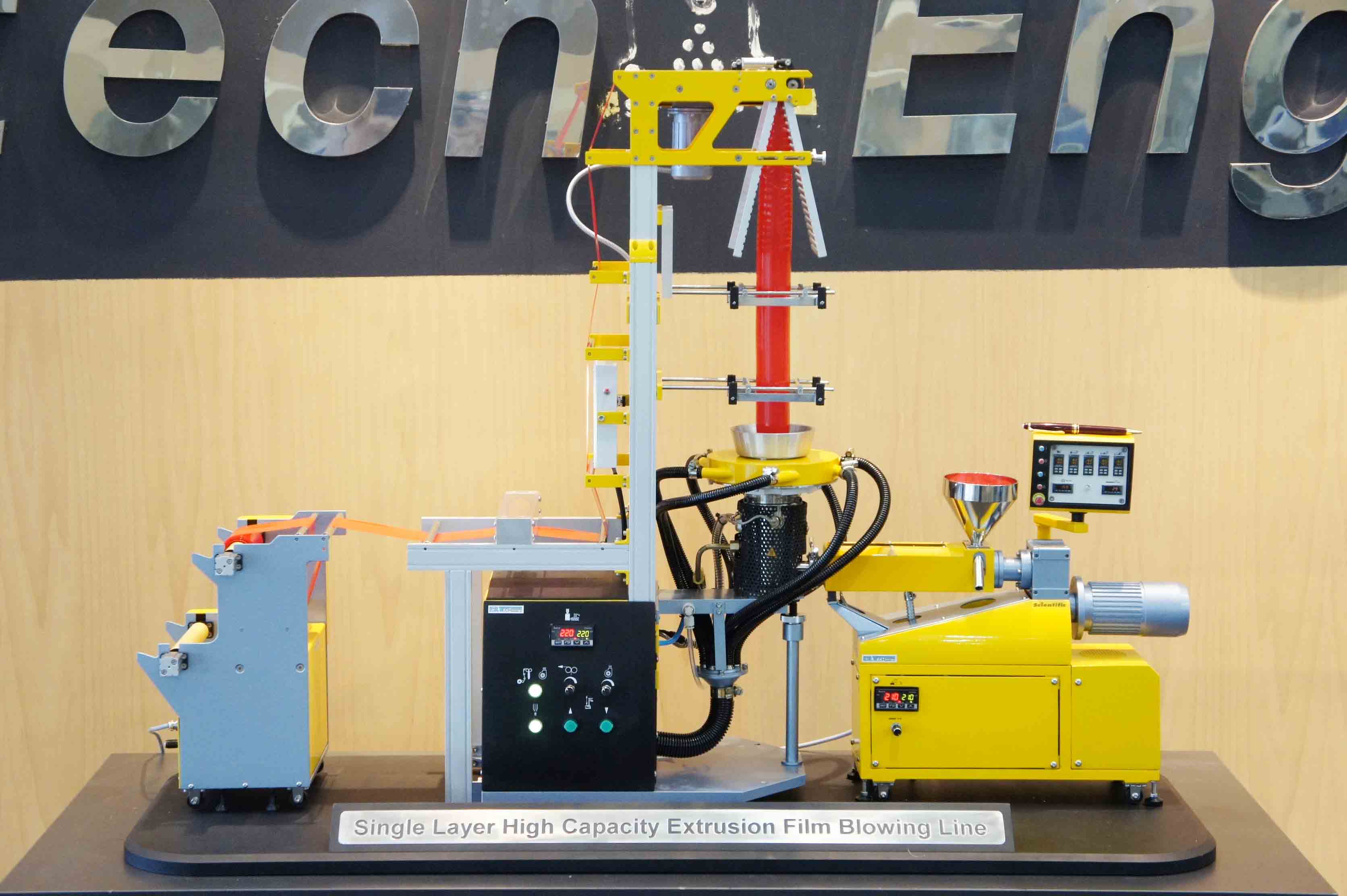

High Output Lab and small production Blown Film lines with 40mm and 45mm extruders, with or without vents. Request a quote on this line - Click Here

|

|

|

|

Dual Station Winders available as an option The two station surface windup system is practical and very easy to use. The film rolls are wound up by friction from the large rubber support roll and the film is guided over a set of rubber following rolls which will ensure content tension for a very even wind up. Changeover of rolls is very fast and easy. It is done by simply removing the whole roll with bobbin and gear shaft and then inserting a new empty bobbin mounted on the additional spare bobbin holder and gear shaft. The windup station is available with 400 and 600 mm roll widths. Request a quote on this line - Click Here

|

|

|

|

Optionally the film tower can be equipped with a two station windup systems where the film windup is driven by a designated torque motor with adjustable film tension. ¨ Load cells are detecting the tension of the film and will adjust the torque drive so that the set tension remains the same at all times, regardless of the diameter of the film roll. The two-station windup system can be used for easy and uninterrupted change over from one roll to another or for winding up individually each part of a split film. For roll diameters up to 600 mm. ¨ The tension is regulated by means of a torque motor drive, one for each station which in turn is connected to a central drive unit. The wind up speeds are typically controlled from the central control panel ¨ The wind up unit is equipped with the practical bobbin free pneumatic expansion shafts which enable a very fast and easy changeover of the rolls. ¨ Same system can also be supplied with only one station on request. Request a quote on this line - Click Here

|

The system has a very user friendly control panel where you can set the tension individually of on each wind up station. The tension can be set digitally also during running of the film. |

|

Technical Data for Blow Film Line

|

|

LF-250 |

LF-400 |

LF-600 |

|

Maximum film |

200 mm |

350 mm |

550 mm |

|

Film speeds, |

Haul Off Nip-Rolls 0 to 15 |

Haul Off Nip-Rolls 0 to 35 |

Haul Off Nip-Rolls 0 to 35 |

|

Height from die |

925-1,184 mm |

950-1,210 mm |

2,000-3,000 mm |

|

Total height |

2,050-2,310 mm |

2,400-2,660 mm |

3,200-4,200 mm |

|

Total electrical power |

4.9 kW |

5.0 kW |

11.0 kW |

Typical Mixing Screw for Single Screw Extruders, 30:1, Maddock Mixer and Pineapple Mixer

Call (810) 516-1700 for Pricing

14042 Iroquois Woods Dr.

Fenton, Michigan 48430